AI engineering and its impact on business

In our 11th iteration of the Technology Circle (15.03.2023), we learned about AI’s role in the production business today and its potential role in the future.

Our four speakers talked about how AI is changing the game of innovation, its role in product development and what companies have to do to avoid falling behind.

Inventing in the era of computerization using TRIZ and AI

Prof. Denis Cavallucci, Professor in Engineering of Innovation at INSA Strassbourg, kicked off the event with a presentation about the most appropriate way to combine human intelligence with digitally assisted invention using TRIZ theory.

We’re facing industrial challenges of highest importance. CO2 neutrality, hydrogen, quantum and feeding the planet are only some of the many areas we’re working on. How we manage to overcome those hurdles depends on the brave problem solvers of our time.

Denis proposes we need to enhance the capabilities of every single problem solver with the power of AI. The web is a vast, ever increasing sea of data. According to recent statistics, it holds 170 million patents, containing about 80% of humanities technical knowledge. Every 1.5 minutes, a new patent gets added. There’s also a new scientific article every 15 seconds and 570 serious websites every minute 0% of the world’s digital data has been created in the last 3 years. All this data could be used to formulate and solve problems. Because no person can read that much, we have to automate the process. That’s where TRIZ comes into play.

What TRIZ is and what it can do

TRIZ is an acronym for Theory of Inventive Problem Solving. Denis summed it up like this:

“TRIZ is a common way of observing problems and shareable solutions through underlying principles. If you can share problems and solutions across disciplines, you may be able to formulate the problem in one discipline and then solve it in another.”

Denis and his team applied the principles of TRIZ to unstructured content to turn any text into usable logic for idea generation.

I = Pb + D

To explain what automatic idea generation means, Denis proposes the hypothesis that an idea is the addition of a problem and data that could solve it.

- I: The result of human interpretation.

- Pb: A problem transformed into a contradiction.

- D: Data extracted from trustful content.

- +: The transdisciplinary pairing of problem and data.

If you bring an engineer a correctly formulated problem and the appropriate data, they can generate ideas to solve it.

To facilitate and ultimately automate this process, Denis and his team built the AIARD Industrial Chair.

The goal is building a set of intelligent tools that accompany users, real time, from expressing their problem to the most relevant scientific information likely to solve it.

Introducing Forvia

Sébastien Trillat, Innovation Global Domain Manager at Forvia, introduces his company and explains why they partnered with the AIARD Industrial Chair. Forvia is a leading global automotive technology company. It’s based on the long-established company Faurecia and is the 7th global automotive supplier.

A few years ago, Sébastien wanted to start working with TRIZ. Forvia partnered with AIARD Industrial Chair to train its employees in the TRIZ methodology. Soon, Forvia saw the potential benefits of dedicating resources specifically to the methodology. That’s when the company hired a young engineer to develop an internal network on TRIZ. Meanwhile, Forvia is already implementing many TRIZ principles to reap the benefits early on. And with great success! A tool they’ve developed together with AIARD Industrial Chair is expected to bring benefits in the double-digit millions.

AI for business leaders—from zero to hero in product development

Prof. Dr. Bernhard Kölmel from the Hochschule Pforzheim & WFG Wirtschaftsregion Nordschwarzwald taught us how decision makers can implement AI in their organizations. He started with a quote from Lord of the Rings.

”The world has changed. I see it in the water. I feel it in the earth. I smell it in the air. Much that once was is lost, for none now live who remember it.

Lord of the Rings

ChatGPT has created a lot of hype around AI. It’s an important topic and experts say that while the hype is at its peak, they don’t expect a bust following it. It’s important to see the big picture. ChatGPT-4 is very impressive but the competition isn’t sleeping. China, for example, has developed a language model even larger than ChatGPT-4! AI is also becoming even more interesting thanks to the Internet of Things (IoT). Almost every machine — even fridges and toasters — collect data that we can use to formulate problems and find solutions.

Companies aren’t used to dealing with easily accessible AI yet. Many think that there are dangers to AI. They try to find these “AI heroes” with the idea of trusting them on every business decision that involves AI. We need to demystify AI and get rid of the “heroes”. Bernhard made a great example why it’s so important.

”It takes experts to repair planes, ships and helicopters. Just because those experts know the vehicle inside and out, doesn’t mean they can run the fleet.

Prof. Dr. Bernhard Kölmel

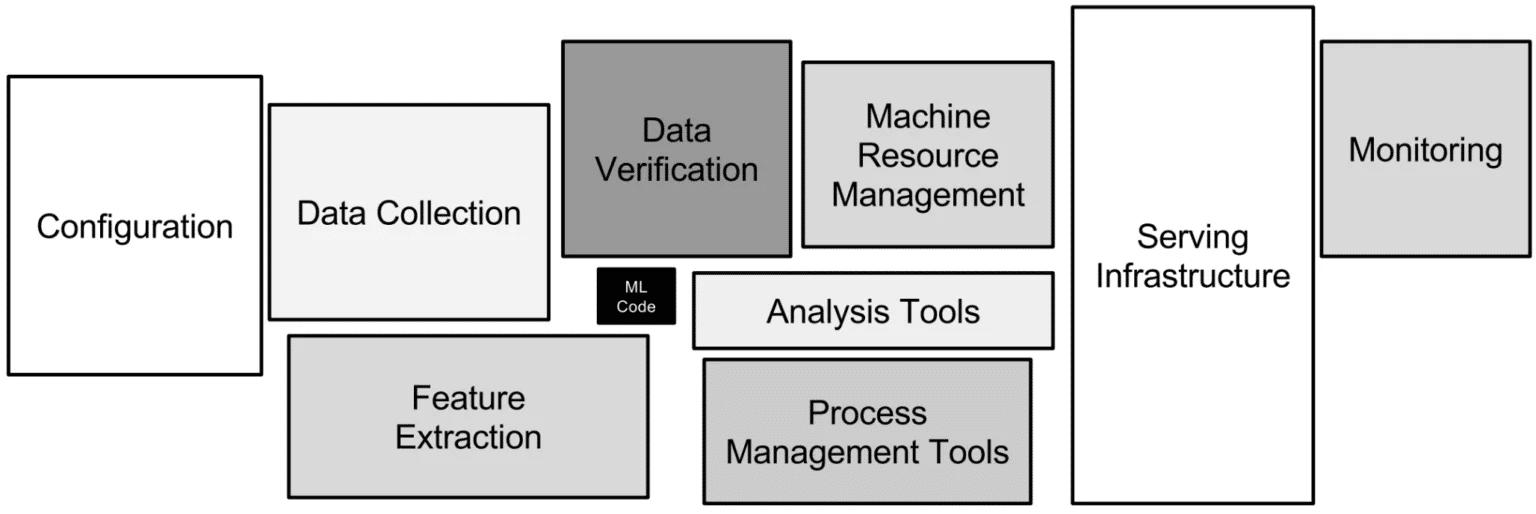

Every decision maker needs to be competent in making AI-involving decisions. AI projects are more than a code. According to a 2014 research paper by Google, only 3% of all AI activities are about the algorithm. The rest is about the work that needs to be done around the algorithm.

Figure: only a small fraction of real-world ML systems is composed of the ML code, as shown by the small black box in the middle. The required sorrounding infrastructure is vast and complex.

Al technologies are complex and relatively new to the business world. Few decision makers understand them. To truly unlock the value of Al, you have to fully integrate it into the fabric of your company. That requires strategies and approaches that understand the science behind AI, the techniques to implement it and the right metrics to measure it’s success. It’s necessary for every company to develop an AI strategy, broken down into concrete, measurable goals. A few examples of AI successfully improving new product development

Bernhard introduces three examples to showcase the power of AI in product development.

- The Volkswagen Group is using Al to improve the efficiency of its production processes. The company has developed an Al system that uses data from the production process to predict quality defects and improve the production process. This has resulted in significant improvements in production efficiency and reduced defect rates.

- Siemens is using Al to optimize the design of its products. The company has developed an Al platform that uses machine learning algorithms to analyze data from product simulations and tests. This has helped Siemens to optimize product designs, reduce development time, and improve product performance.

- Bosch is using Al to develop new products. The company has set up an Al research center that focuses on developing Al-powered products, such as smart home systems and autonomous vehicles. This has helped Bosch to diversify its product portfolio and stay ahead of the competition.

To decide on what AI project your company should work on, Bernhard recommends the AI Project Canvas, modelled after the famous Business Model Canvas. Here is where you can find it with a detailed explanation:

Getting better on your own — Automatic optimization of advanced robotic applications

Dr.-Ing. Darko Katic from ArtiMinds GmbH in Karlsruhe showcased how ArtiMinds uses AI to realize the full potential of advanced robotics. Darko puts his company’s mission simply:

”We create software to program robots more easily in all stages of robotic applications: planning, programming, installation, deployment, analysis and optimization.

Dr.-Ing. Darko Katic

To do that, ArtiMinds has two solutions. First, the Robot Programming Suite (RPS) enables developers and process experts to program industrial robots in an easy, intuitive fashion. Second, the Learning & Analytics for Robots (LAR) collects all data coming from a robot and helps analysts interpret it in a meaningful way.

Currently, a lot of manufacturing happens in low income countries. There’s a risk to that as we’ve seen with the pandemic or the war in Ukraine and the respective production issues. We need to bring production back into our own country. The only way to match the cheap labour cost is by using advanced robots.

Robots are very good if they can repeat the same task over and over again without having to adjust to anything. In reality, manufacturing isn’t that easy.

- No two work pieces are the same: there might just be a mm difference between them, impossible to see with your naked eyes. If a piece doesn’t fit, we adjust it intuitively. A robot can’t.

- Something might be “broken”: if a pin on a circuit board is slightly bent, the robot can never fit anything on it. A human would just bend the pin back.

- Not all pieces are rigid: cables, for example, might fall in a weird position or even tangle up. While a human can untangle them easily, a robot can’t work with them anymore. Those are just three of the many challenges we’re facing in advanced robotics.

The robot needs to be able to understand the problem. With sensors, the robot can see and feel the parts its working with. Almost like a human would. If, for example, it needs to insert one piece into another, it’ll register resistance if the pieces don’t fit. It’ll then adjust the position until there is no resistance anymore. With lasers and cameras, the robot recognizes the parts and their positions to adjust itself, making it possible to automate the production with cables and tubes.

It’s fairly easy to make these solutions work in a controlled setting. But getting them production-ready is a different story. That’s why we introduced data driven analysis and optimization. Everything the robot does generates data which we can attribute to a specific action. We collect and visualize this data to make it possible for engineers to easily identify flaws and mend them. A mistake can take only milliseconds and nanometers. An engineer needs the visualization of the data to see it.

Our AI already generates possible solutions to the problems for the engineers to simply verify and implement. The next goal is to enale the robot to learn from its mistakes and make the adjustments itself with the help of a digital twin.

Let us introduce ourselves

The Industrial Transformation initiative: Realize digital transformation in your company.

The production industry is a significant economic sector in the Basel Area. To help companies succeed, we bring together stakeholders from industry, academia and startups to collectively advance innovation in the field of Industry 4.0.

Our Industrial Transformation team’s activities include:

- A series of public events for the industry dedicated to technologies important for the innovative development of our tri-national region.

- Promote cooperation between entrepreneurs and academia.

- Technology circles Industry 4.0 Events and workshops on Industrial transformationIoT and advanced technologies for digital transformation.

- An AI4 and SME program for the collective and concrete development of Proofs of Concept with Artificial Intelligence Innovative solutions for the production industry.

- The i4Challenge accelerator for SMEs, startups and new ideas for Industry 4.0.

Share this article

Sign up to receive our newsletter in your inbox.

You may also be interested in

The power of a persuasive pitch deck

Roche investing an additional 1.2 billion Swiss francs in Basel

Nouscom secures 67.5 million euros in financing

Celebrating six months of innovation: i4Challenge accelerator New Ideas 2022/2023

How open innovation in healthtech hubs is fueling the rise of digital healthcare

How to access the U.S. market with your medical device

Sébastien Meunier Director Industrial Transformation.

Sébastien Meunier joined Basel Area Business & Innovation in 2016. Prior to this, he was Cleantech Manager at i-net innovation networks switzerland.

”Are you interested in innovation and networking? In our Trinational Industry 4.0 Technology Circles we bring together researchers, developers, entrepreneurs and other stakeholders for cross-disciplinary exchange.

Sébastien MeunierDirector Industrial Transformation